Bronze Studio

To learn about the wax sculpting and spruing process that proceeds this, check out Wax Studio.

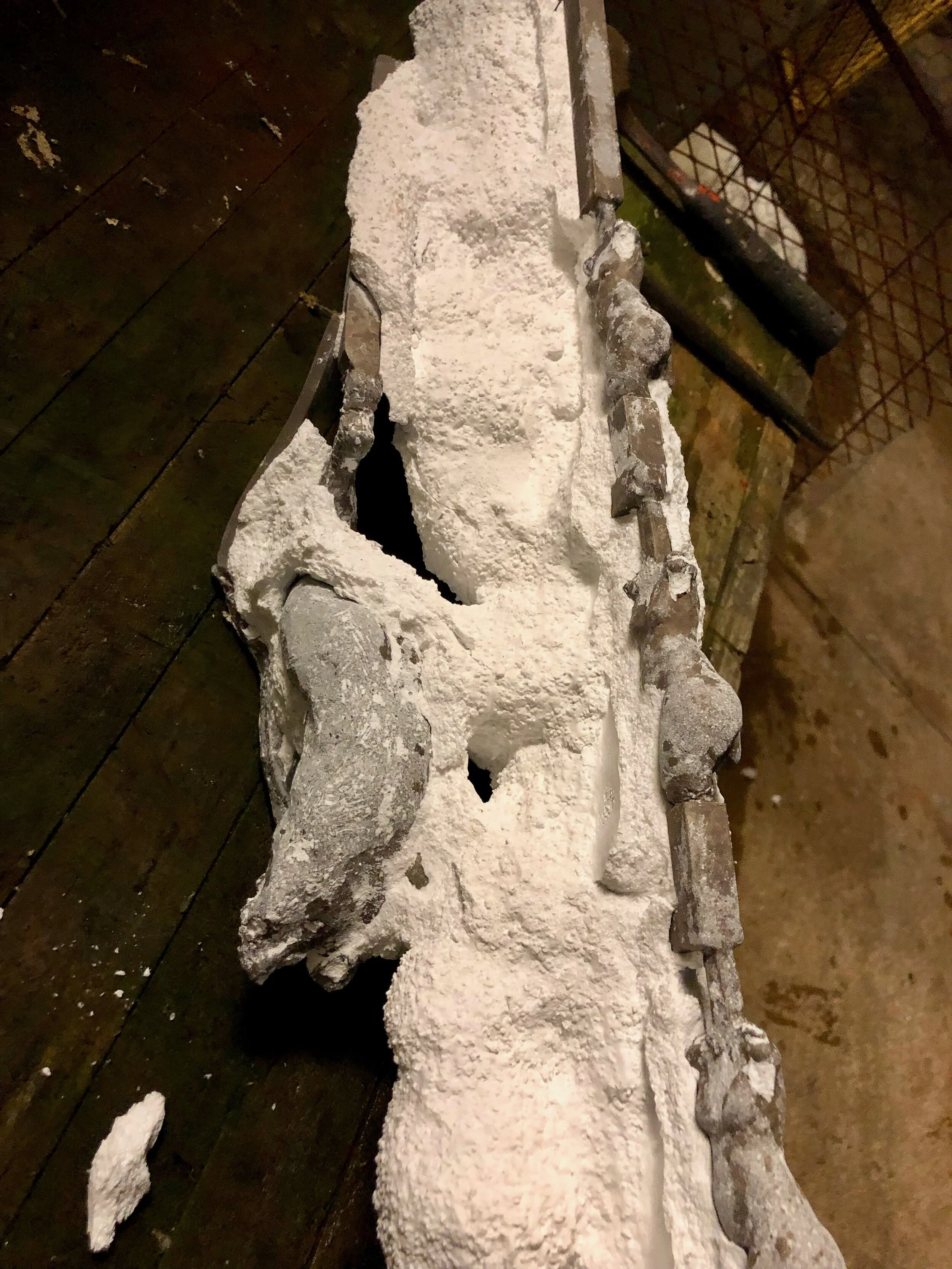

Sprue systems are dipped in silica slurry and covered in silica grit over a period of days, building up the silica to form a shell around the wax. This system is then fired, melting out the wax and producing a hard ceramic shell mould. The shells are then filled with molten bronze and left to cool. Once cool, the ceramic shells are removed from the cast bronze with chisels, hammers and sandblasters. The sculptures are then cut from the remaining bronze sprue system and are chased with metal working tools to hide signs of the sprue system and to fix blemishes. When sculptures have been chased and assembled to the satisfaction of the artist, they are finished with a patina which is made from layering chemicals on the surface of the bronze at different temperatures.

To view finished pieces, visit the Bronze sculpture page.